About Us

Being a quality conscious company,We strive to offer the best quality of products and services.

Introduction

- KAKADE CNC SERVICES has well-educated staff & designers, assisted with latest computer technology & software & can take-up any challenging jobs with condence

- NATURE OF ACTIVITY - Nature of Activity & Capability – Machining & supply of precision engineering components & Patterns & Die making

- PRODUCTS RANGE - Auto Components - Like Engine Front Covers, Flywheels, Transmission Housing and Covers, Brake Drums, Pulleys, Timing Gears, Hubs, Oil Seal Retainers, Exhaust Manifolds, Bearing Covers, Brackets and Thermostat Housing .

- FUTURE SCOPE - Simultaneous 5 - Axis to be Planned (HASS UMC 700 ) & Millipore Testing with particle size machine .

Kakade CNC Services , was founded in yr.2000 (19 yrsback) by installing only 2 VMC machines (1st in Kolhapur), with the intention of machining of high class quality Auto Components to be supplied to Auto Companies / Export / other engineering customers. In the last 19 yrs the Company having 28 VMC Machines and has also developed in house facilities of Fixturing / Pattern & Die Making. The Company can now boast the quality & timely delivery at reasonable price.

Quality Policy

- We at, Kakade CNC Services are committed to satisfy our customers and fulll applicable requirements through manufacturing of cost effective products at highest quality standards with timely deliveries.

- We achieve the same by involvement, co-operation, and quality consciousness across the organization and continual improvement in effectiveness of quality management system.

Quality Objectives

- Consistent product quality

- On Time delivery

- Continual improvement of QMS processes

- Upgradation of employee skills

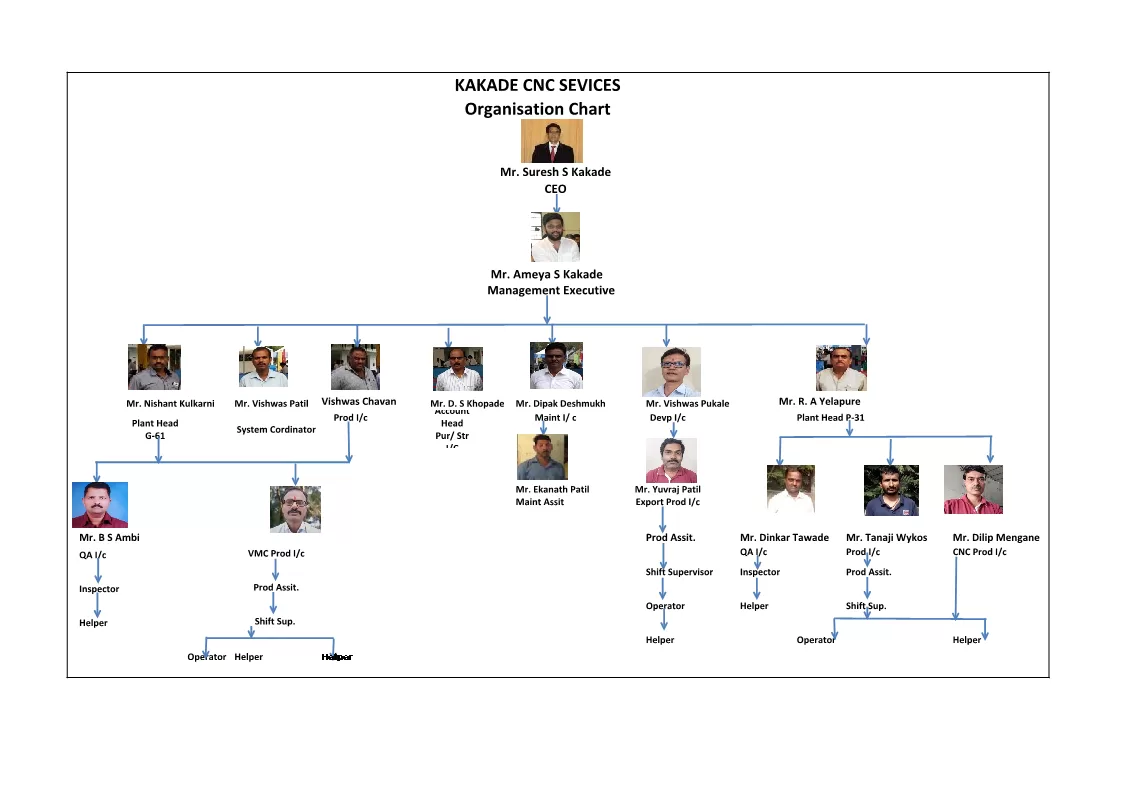

Our ORGANIZATION

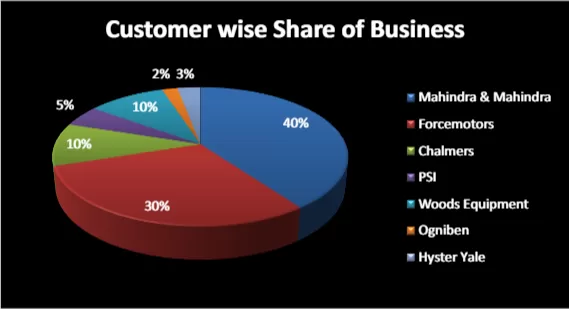

Turnover & Market Share

Our Success – Products and Strategies that Truly Deliver on

what they Promise, without Compromise .We engage with our

customers to understand their needs and provide a customized

solution that cater to their specific needs

Employee Motivation

A Group as large and diverse as Kakade CNC Services requires a process that encourages bonding among managers and workers –across locations, companies and functions. With this objective, the ‘Kakade CNC Services ’ brings talented team along with their spouses . While making friends with colleagues and having a relaxed time, the our team get acquainted with the their leadership.Our Team processes including induction program, training sessions, performance management and reward and recognition programs are aimed at reinforcing our values across all levels.

Explore Our Expertise

Auto Components – such as Engine front covers, Flywheels, Transmission housing & covers, Brake drums, Pulleys, Timing gears, Hubs, Oil seal retainers, and Exhaust manifolds – are designed to meet the highest standards of quality and performance.

ISO 9001-2000 Certified by ISC (Australia), we proudly operate our own foundry, with a capacity of 150 tons per month for both Cast Iron and S.G. Iron.

Quality Assurance - 25

Skilled Workers - 105

Semi Skilled - 25

Unskilled - 15

Office Staff- 07

We can develop and supply precisely finished, high-quality precision auto components with material, as per requirement, within 4-6 weeks. Additionally, we also make dies and patterns according to customer specifications.

Nature of Activity

Supply and machining of auto components

Design and machining of dies and patterns

Exclusive Addons

Default description

Experiance in the field

Machine shop – With over 25 years of experience

Foundry – Boasting 20 years of expertise

Exclusive Addons

Default description

Valued customers

Mahindra & Mahindra Ltd, Mumbai

Force Motors Ltd, Pune

Woods Equipments, USA [Export] – Serving international markets

Exclusive Addons

Default description

Testimonials

We take pride in delivering high-quality CNC machining services that not only meet but also exceed our clients' expectations. Here’s what they have to say about working with us.

We’ve partnered with Kakade CNC Services for multiple CNC machining projects, and their attention to detail is unmatched. Moreover, the precision, quality, and turnaround have been outstanding every time.